B9 Shipping – Feasibility Study Successfully Completed

— 21 Mar 2013

Wind tunnel testing the B9 sailing cargo ship

Spring 2012 saw the completion of an exciting tranche of work undertaken by Humphreys Yacht Design and the Wolfson Unit – this was the first stage feasibility study for the B9 Shipping into the development of a modern, environmentally friendly and economically advantageous sailing cargo ship design.

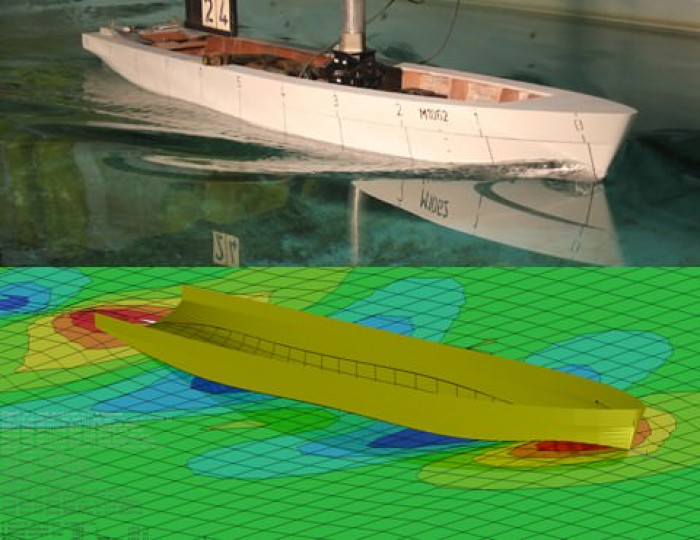

The design process commenced with an investigation into a wide range of hull parameters using our in-house CFD and VPP software. While the general concept will be applicable to a broad range of ship types, for the feasibility study we focused on the 3000-4000 DWT cargo vessel sector, and we continuously benchmarked against a generic conventional freighter within this sector.

The ability to carry sail places a direct emphasis on transverse stability and the ability to generate side force. These are features common to all sailing vessels, though long since removed from the design of commercial ships since the clipper days of old. In addition to these stability and side force requirements, the ship must also be more manoeuvrable than a conventional commercial vessel and capable, for example, of responding to a shifting breeze. The initial design process focused on fairly broad issues – namely how best to package the large volume required to deliver the cargo carrying capacity and how best to distribute this volume to provide sufficient stability and manoeuvrability as well as efficiency at a range of leeway and small heel angles. For us it is perhaps surprisingly analogous to some of our normal design work – where we are trying to ‘hide’ displacement into as easily driven hull shape as possible. In this respect Rob Humphreys felt it very reminiscent of designing IACC hulls for the America’s Cup.

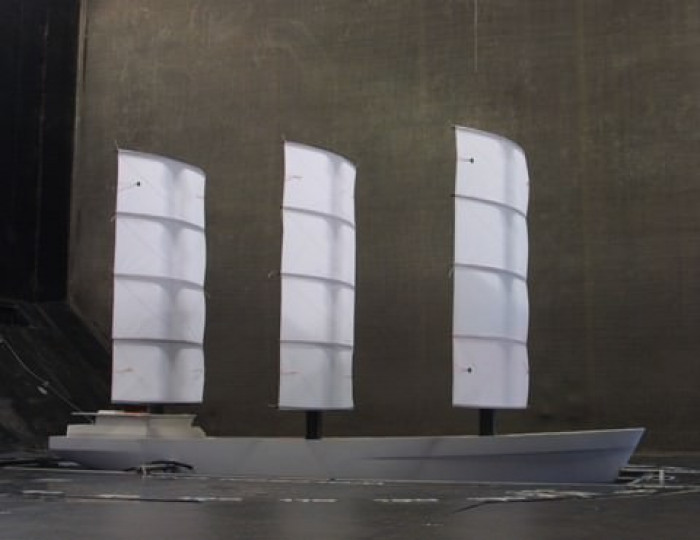

Various rig concepts are under consideration, seeking compromise between efficiency, manning requirements and capital expenditure. There are pointers to be drawn from history and the need to break the sails and components down into manageable and serviceable units is clearly vitally important, drawing us closer to the distant past than to current fore-and-aft rig technology with which we are so familiar. The iteration of the Dynarig, so very ably developed for ‘Maltese Falcon’ by Gerard Dijkstra and Damon Roberts, represents one highly successful iteration of an age-old square-rig concept, but the challenge for us is to develop an industrialised solution to a multi-panel rig that is not over-reliant on commercially unaffordable technology. Whilst there is good will and green incentive for wind-powered ship development, we believe very strongly that for it to really work, the business proposition has to be able to stand up for itself without depending on political incentive.

The towing tank and wind tunnel data has provided the project with an excellent starting point. In conjunction with the Wolfson Unit, we now have a fully developed velocity prediction program for the vessel and much work is now being put towards the economic modelling for various shipping routes, this section of the work being carried out by a specialist UCL team working with the Met Office and maritime software-developer Graeme Winn. An exciting collaborative network of project partners is being assembled, allowing the project to benefit from a wealth of knowledge across a wide range of specialist fields. We hope to be able to bring you more exciting news on this project in the not too distant future but in the meantime, for more information, please visit the B9 Energy Group website.